DTF Transfers, or Direct-to-Film transfers, have revolutionized the custom apparel printing industry by offering an efficient method for transferring designs onto various materials. This innovative technology utilizes a specialized printing process that ensures vibrant colors and intricate details, making it a fantastic choice for personalized printing. As printers seek to meet the growing demand for customized products, understanding DTF printing benefits becomes essential. Not only does DTF technology simplify production workflows, but it also accommodates a wide range of fabrics, increasing its appeal among diverse customer bases. In this article, we will explore the rise of DTF transfers and why they are vital for every printer in today’s competitive market.

When discussing modern printing techniques, it’s impossible to overlook the significance of Direct-to-Film technology in the realm of custom printing solutions. This method streamlines the application of detailed artwork onto fabric, allowing brands and businesses to deliver personalized items swiftly and efficiently. With its ability to cater to a variety of materials and its user-friendly approach, the market for DTF transfers continues to expand. Printers are increasingly adopting this advanced technique to enhance their offerings and stay relevant in an evolving industry. As we delve into the various aspects of this dynamic printing method, it becomes clear why understanding DTF is crucial for anyone aiming for success in today’s apparel market.

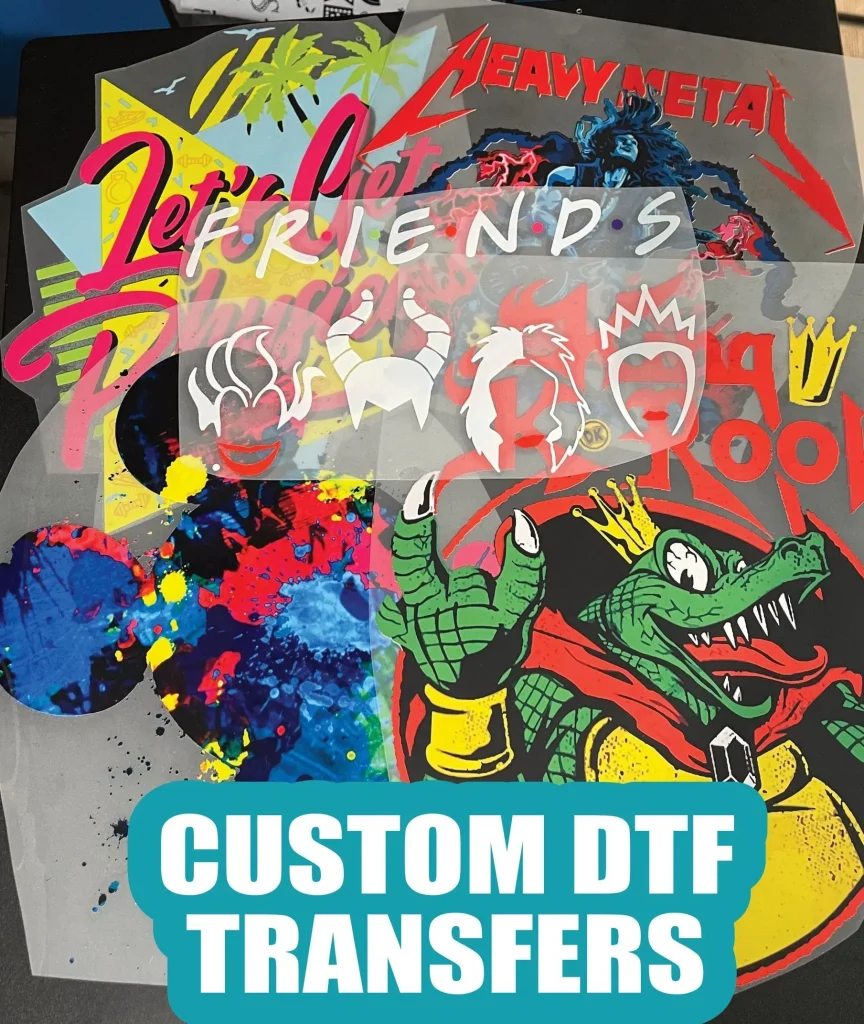

What is DTF Printing?

Direct-to-Film (DTF) printing represents a groundbreaking step in the field of custom apparel printing. This revolutionary technique first involves the meticulous process of printing designs onto specially crafted film. Unlike traditional printing methods that often require complex setups or extensive preparation, DTF simplifies the workflow by allowing designers to work directly with the film. Once printed, the film is coated with an adhesive powder, enabling the unique transfer process to thrive—this provides printers with the flexibility to produce higher quantities of intricate designs without sacrificing quality.

This versatility includes a growing repertoire of material applications. DTF transfers effectively bond to various fabrics such as cotton, polyester, and even blends, thus making it an optimal choice for companies looking to diversify their offerings. As consumers seek personalized and dynamic apparel options, understanding the basics of DTF printing becomes increasingly essential for every printer aiming to stay at the forefront of innovation.

Benefits of DTF Transfers in Custom Apparel

One of the standout benefits of DTF transfers is the unparalleled quality and detail they produce. With vibrant colors and sharp line resolution, DTF printing ensures that every design aspect, from logos to intricate graphics, strives for perfection. This is particularly advantageous in custom apparel printing where brand representation depends heavily on visual appeal. Compared to competing printing methods, DTF maintains consistency while effectively handling detailed designs, thus enhancing the overall consumer experience.

In addition to quality, DTF transfers boast incredible material versatility. Printers will find that they can apply these transfers to an extensive range of fabrics, significantly expanding their service capabilities. This adaptability means that printers can cater to diverse customer needs, whether the request is for high-end fashion pieces or casual sportswear, while maintaining competitive pricing. Thus, DTF has become a catalyst for increased sales opportunities within the custom apparel market.

Streamlined Production with DTF Technology

One of the most compelling reasons to adopt DTF technology is the ease of use that significantly enhances production efficiency. The streamlined nature of the DTF process allows printers to minimize the number of steps needed to complete a project. Instead of juggling multiple techniques and tools, the DTF workflow integrates seamlessly, facilitating faster turnarounds on orders. This aspect is crucial for both new printers entering the market and seasoned professionals seeking to optimize their operations.

For businesses seeking to thrive in today’s fast-paced environment, DTF allows for the rapid fulfillment of orders without sacrificing quality. Compared to traditional methods that often are labor-intensive and time-consuming, DTF embraces simplicity, ensuring that more time can be dedicated to actual production rather than setup. This ease of use not only opens pathways for innovative designs but also attracts more clientele due to quicker service delivery.

DTF Printing Meets Market Demand for Personalization

In today’s consumer landscape, the demand for customization and personalization is surging. DTF printing is uniquely positioned to meet this growing inclination for customized products. Whether for individual consumers or brands looking to showcase their unique identity, DTF technology offers a quick and cost-effective solution to deliver on these demands. Printers adopting DTF can effectively cater to a wide variety of custom orders, setting themselves apart in a competitive marketplace.

Moreover, as e-commerce continues to grow, businesses that embrace personalized printing solutions see a notable increase in customer satisfaction and loyalty. Offering DTF transfers allows printers to provide bespoke solutions that resonate with customers, whether through personalized apparel, unique promotional items, or one-off creations that enhance brand visibility. By focusing on individual customer needs, printers leveraging DTF technology can position themselves as market leaders in a demand-driven economy.

Sustainable Practices in DTF Printing

With increasing global awareness of environmental issues, sustainable practices in printing are no longer optional but essential. DTF printing technology is evolving to meet these demands through eco-solvent inks and environmentally friendly materials. Companies adopting DTF technology stand to benefit from incorporating sustainable practices, which not only appeal to environmentally conscious consumers but also bolster their brand image.

Sustainability in DTF printing encourages higher levels of ethical awareness among printers, fostering a culture of responsibility that resonates with both employees and clients. By aligning with sustainable practices, printers not only enhance their marketability but also contribute to broader environmental goals. This commitment to eco-friendliness in custom apparel printing positions DTF as a forward-thinking choice for businesses aiming to adapt to contemporary manufacturing expectations.

Future Trends in DTF Technology

Looking forward, the technological advancements in DTF printing signal a bright future for this printing method. Continuous improvements in ink formulations ensure better adhesion and durability of prints, crucial in producing high-quality, long-lasting products. Additionally, innovations such as automated printing processes reduce human error and improve production speed, further solidifying DTF’s status as a frontrunner in the custom apparel sector.

As the printing industry continues to evolve, staying abreast of these trends is pivotal for printers looking to remain competitive. Analysts forecast that DTF printing will soon be widely adopted as a standard in the industry, paving the way for new business opportunities and growth. For printers willing to embrace DTF technology today, the potential for success in tomorrow’s market is boundless.

Frequently Asked Questions

What are DTF transfers in printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special transfer film that is later applied to fabrics using heat. This process allows for vibrant colors and intricate details, making it a popular choice in custom apparel printing.

What are the benefits of using DTF printing technology?

DTF printing technology offers several benefits, including high-quality prints with vibrant colors, material versatility for various fabrics, and user-friendly processes that simplify custom apparel printing. It’s ideal for producing detailed graphics and meeting the growing demand for personalized printing.

How does DTF technology compare to traditional printing methods?

Compared to traditional printing methods, DTF technology simplifies the workflow by reducing the number of steps needed for production. This ease of use, coupled with its capability to produce high-quality, detailed prints on different materials, makes DTF a preferred choice for many printers.

Can DTF transfers be applied to any type of fabric?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics including cotton, polyester, and blends. This versatility allows printers to cater to diverse customer needs in the custom apparel market.

How are businesses benefiting from the rise of DTF printing?

Businesses benefit from DTF printing by meeting the rising demand for personalized and customized products. The technique’s cost-effectiveness and ability to produce high-quality prints enable printers to fulfill low-volume custom orders efficiently, increasing their sales opportunities.

What training options are available for mastering DTF printing?

For those looking to master DTF printing, various resources such as workshops, online courses, and tutorials are available. These training options help printers enhance their skills and adapt to the growing market of personalized printing, ensuring they remain competitive.

| Key Points | Details |

|---|---|

| Definition of DTF Transfers | Direct-to-Film (DTF) transfers involve printing designs on a special film, which is heat pressed onto different materials. |

| Advantages | DTF offers high-quality prints, detailed designs, versatility across various fabrics, and ease of use for new and experienced printers. |

| Market Growth | DTF meets the increasing consumer demand for customized products in the garment industry. |

| Industry Trends | Emphasizing sustainability, flexibility for custom orders, and automation in the printing process. |

| Technological Innovations | Advancements in ink formulations and automated processes enhance efficiency and print quality. |

| Future Prospects | DTF is predicted to become a standard in printing, essential for competitive advantage. |

| Resources for Training | Workshops and online courses are available for printers to master DTF techniques. |

Summary

DTF Transfers have emerged as a pivotal advancement in the printing industry, revolutionizing how designs are applied to various materials. This innovative technology enables printers to produce high-quality, detailed prints with incredible ease, making it an essential method for anyone in the printing business. The versatility of DTF allows for a broad array of materials to be printed on, catering to the growing consumer demand for personalized and unique products. As the landscape of printing technology continues to evolve, embracing DTF Transfers is not just an option; it is a necessity for those looking to thrive in a competitive market. By understanding the nuances and benefits of DTF, printers can position themselves for success and meet the ever-changing needs of their customers.