DTF transfers, or Direct to Film transfers, have revolutionized the way we approach merchandise design, providing a vibrant and durable alternative to more traditional printing methods. This innovative technique allows for intricate designs to be printed onto specially designed films, which can then be heat-pressed onto a variety of fabric surfaces. Whether you’re creating custom merchandise for a small business or a personal project, understanding the ins and outs of DTF transfers can elevate your products to a professional level. In this post, we’ll delve into essential merchandise design tips and techniques to maximize the impact of your DTF prints. From selecting the right transfer film quality to mastering heat press techniques, we’ll help you create eye-catching pieces that are sure to impress.

Also known as Direct to Film printing, DTF technology is gaining popularity among creators seeking to produce high-quality textile designs. This method involves transferring printed designs onto a specially coated film, which is then applied to fabric surfaces using heat and pressure. As you explore options for creating custom merchandise, it’s important to consider aspects like transfer film quality and application methods. With effective heat press techniques and a grasp of merchandise design principles, you can achieve stunning results that resonate with your audience. In this guide, we will explore the essential tips for mastering the DTF process to enhance your product offerings and ensure lasting impressions.

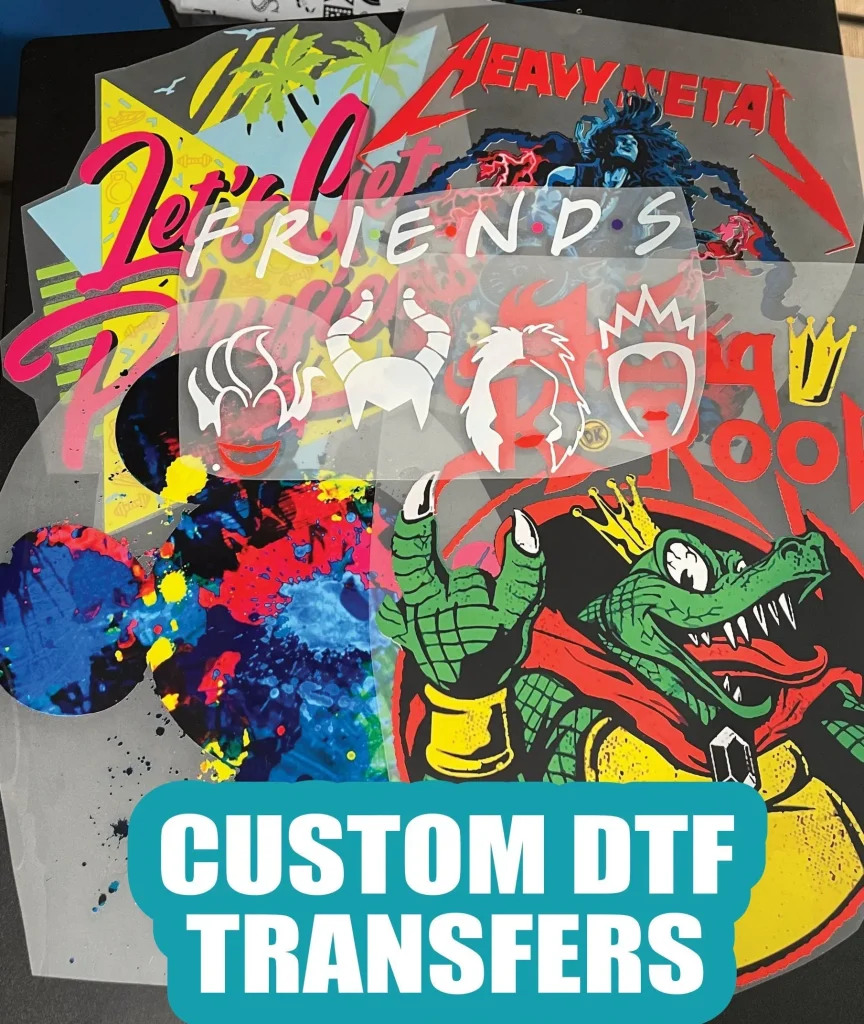

Understanding DTF Transfers and Their Benefits

Direct to Film (DTF) transfers have revolutionized the way designs are applied to fabrics. This cutting-edge technique enables you to print vibrant images on a special film that can be transferred onto various types of materials, creating stunningly detailed finished products. One of the primary benefits of using DTF transfers is their versatility; they can be applied to a wide range of fabrics, from cotton to poly-cotton blends, making them ideal for various merchandise designs.

Additionally, DTF transfers are known for their durability. When applied correctly, these transfers withstand multiple washes without fading or peeling, thus ensuring that your merchandise retains its appeal over time. This durability is particularly important for businesses looking to provide high-quality products that customers will cherish, making DTF transfers a wise choice for creating eye-catching merchandise.

Crafting High-Contrast Designs for Maximum Impact

When it comes to creating merchandise that stands out, high-contrast designs are essential. Selecting vibrant and distinct colors within your designs not only grabs attention but also enhances visibility, especially against varied fabric colors. Look for color combinations that resonate with your brand identity and consider experimenting with dark and light contrasts to see what works best.

Using vector graphics can significantly enhance your ability to create these impactful designs. Vector images are versatile and can be resized without losing clarity, allowing for flexibility in your merchandise designs. Whether you’re producing small items like patches or large apparel, high-contrast vector designs ensure that every piece remains sharp and visually appealing, driving customer interest.

Selecting Quality Transfer Films for Success

The quality of transfer films plays a critical role in the success of your merchandise. Poor quality films can result in designs that crack, peel, or fade after the first wash, leading to customer dissatisfaction. Therefore, sourcing DTF films from reputable suppliers who prioritize quality can significantly affect the performance and appearance of your finished products.

Investing in high-quality DTF transfer films not only enhances the aesthetic appeal of your merchandise but also contributes to its longevity. High-grade films promote better adhesion and vivid prints that elevate your merchandise from ordinary to exceptional, creating a strong impression that keeps customers coming back for more.

Print Settings: The Key to Exceptional Merchandise

Optimal print settings are crucial when creating DTF transfers that look professional. Adjusting your DPI settings can make a significant difference in the clarity of your designs – the higher the DPI, the sharper your images will appear. Experimenting with different settings allows you to find the sweet spot that balances speed and quality while avoiding common printing pitfalls like blurriness.

By taking the time to perfect your print settings, you not only enhance the visual quality of your merchandise but also streamline your production process. This attention to detail is vital in meeting customer expectations and ensuring that your products stand out in a competitive marketplace.

Heat Press Techniques: Getting It Just Right

Mastering heat press techniques is fundamental to effective DTF transfers. Each transfer requires a precise application of heat and pressure to ensure optimal adhesion and durability of the design. Following the manufacturer’s guidelines closely for temperature settings—typically between 320°F to 350°F for 10 to 15 seconds—is essential to prevent damage to the fabric or the design.

Improper heat press settings can lead to issues such as uneven prints, cracking, or fading of the design, which can significantly detract from the overall quality of your merchandise. By perfecting your heat press techniques, you can ensure that every transfer comes out flawlessly, adding to the professional quality of your products.

Post-Transfer Care: Prolonging the Life of Your Merchandise

Proper care after applying your DTF transfers is essential for ensuring the longevity of your merchandise. Allowing transfers to cool completely before peeling off the film is critical for the design’s adherence to the fabric. This step is often overlooked, but an adequate cooling period can significantly enhance the durability of the design.

Additionally, adhering to specific washing and cleaning guidelines post-transfer helps maintain the vibrant quality of your merchandise. For instance, avoiding bleach and washing items in cold water can dramatically prolong the life of your prints, ensuring that customers remain satisfied and your products continue to shine.

Frequently Asked Questions

What exactly are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, is a modern printing technique where designs are printed onto a special film, which is then transferred onto fabrics using a heat press. This method allows for vibrant and durable designs that are perfect for custom merchandise.

What are some merchandise design tips for using DTF transfers effectively?

To create eye-catching merchandise with DTF transfers, choose high-contrast vector designs for clarity and appeal. Ensure you use high-quality transfer films and adhere to the recommended heat press techniques for optimal results.

How can I ensure the quality of transfer films for DTF printing?

Investing in high-quality DTF transfer films is crucial; always source films from reputable suppliers. This prevents issues like peeling or fading, ensuring your merchandise maintains its vibrant look and durability over time.

What heat press techniques should I follow for successful DTF transfers?

For effective DTF transfers, follow the manufacturer’s guidelines for heat settings, typically between 320°F to 350°F for 10 to 15 seconds. Mastering these heat press techniques is vital for ensuring the longevity and clarity of your designs.

Are there specific fabrics that work best with DTF transfers?

DTF transfers are most compatible with cotton and poly-cotton blends. It’s advisable to test your transfer on different fabric types to ensure optimal results and durability of your designs.

How should I care for merchandise printed with DTF transfers?

For post-transfer care, allow the design to cool before peeling off the film. Follow washing guidelines such as using cold water and avoiding bleach to preserve the quality and longevity of your DTF printed merchandise.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Modern printing technique that transfers designs onto fabrics using special film. Known for vibrant, durable prints. |

| Choosing the Right Design | Opt for vibrant, high-contrast vector graphics for quality and visibility. |

| Quality of Transfer Films | Use high-quality DTF transfer films to prevent peeling or fading of designs. |

| Print Settings Matter | Adjust DPI settings for clarity; higher DPI equals clearer images. |

| Adhesion Techniques | Use high-quality adhesive powder to ensure lasting adherence of prints. |

| Mastering Heat Press Techniques | Set heat press at 320°F-350°F for 10-15 seconds for successful transfers. |

| Fabric Compatibility | Best results on cotton and poly-cotton blends; test on different fabrics. |

| Post-Transfer Care | Allow cooling before peeling film, follow washing guidelines to prolong design life. |

Summary

DTF transfers are a revolutionary method for creating visually compelling merchandise that captivates customers. By understanding the critical components such as design selection, quality materials, and appropriate techniques, businesses can harness the full potential of DTF transfers. This approach not only enhances the aesthetic appeal of the products but also ensures their durability and longevity, setting your merchandise apart in a competitive market.