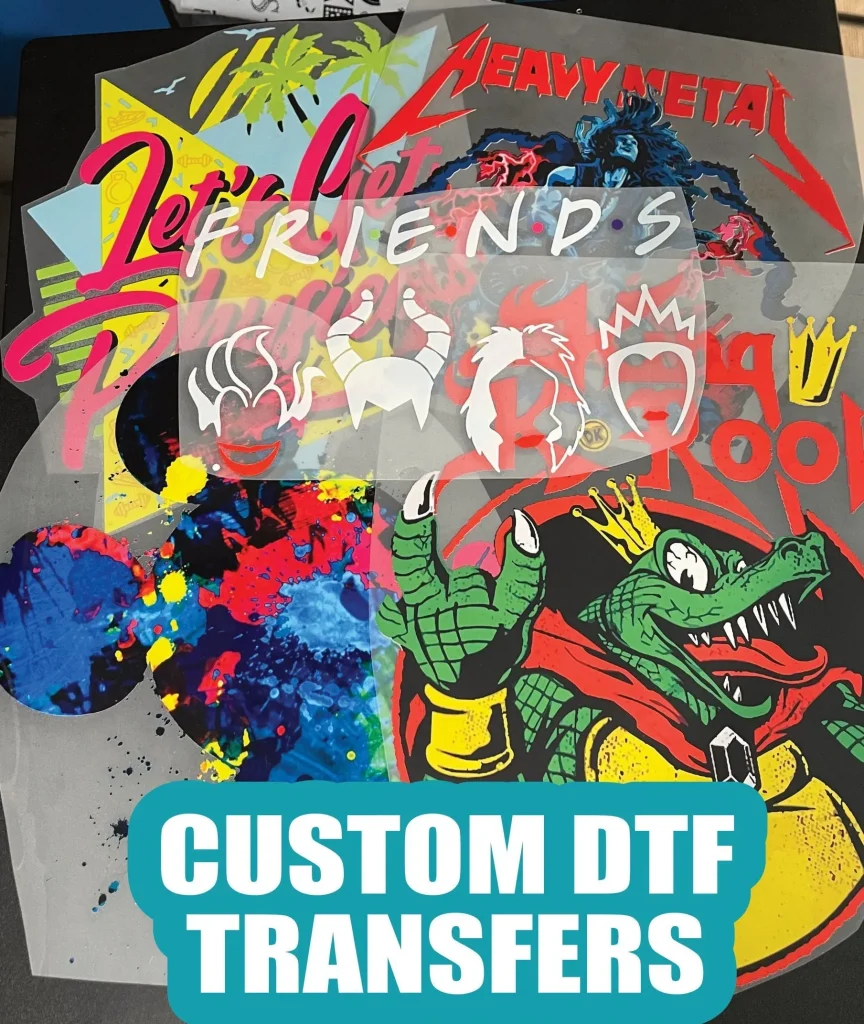

In the realm of custom apparel, DTF transfers have revolutionized the way designs are printed, marrying the precision of Direct to Film printing with the flexibility needed for various fabric types. This innovative DTF printing process offers a fantastic solution for those looking to achieve vivid color prints and intricate designs without the complexities often associated with traditional methods. Whether you’re a small business owner or an enthusiastic hobbyist, mastering DTF transfers can set you apart in a competitive marketplace. This guide provides essential DTF transfer tips and insights into the advantages and quirks of this growing trend in custom apparel printing. Join us as we dive into the exciting world of DTF transfers and explore how you can elevate your fabric printing game.

When discussing innovative printing techniques, the term ‘DTF printing’ might not be as familiar to many as traditional methods, but it’s quickly gaining traction for its unique applications in fabric decoration. Often referred to as Direct to Film, this approach utilizes a specialized film to transfer vibrant, detailed images onto a variety of textiles. The custom apparel printing landscape is being transformed by DTF transfers due to their versatility, affordability, and ease of use. As businesses seek efficient solutions for producing high-quality garments, understanding the DTF printing process and its myriad advantages becomes increasingly important. This guide aims to unpack the intricacies of DTF transfers, offering valuable insights and strategies for anyone looking to champion custom design through this dynamic technology.

The Basics of Direct to Film Printing

Direct to Film (DTF) printing is a revolutionary technique that merges the benefits of traditional screen printing with the flexibility offered by digital technologies. The process begins with creating high-quality artwork, which is then printed onto a specialized DTF film. This film acts as a transfer medium that carries the design to various fabric types. The result is a vibrant, durable print that can withstand multiple washes, making DTF a preferred choice for custom apparel businesses.

The DTF printing process is relatively straightforward, but it requires specific components to achieve optimal results. Key equipment includes a compatible DTF printer, adhesive powders, and a reliable heat press. By ensuring that all equipment and materials are correctly matched and maintained, printers can replicate stunning designs, enhancing the appeal of their custom apparel offerings. This technology not only simplifies the printing process but also empowers designers to push creative boundaries.

Key Components and Equipment for DTF Printing

To get started with DTF transfers, understanding the essential components of the printing setup is crucial. A specialized DTF printer is at the heart of the process, utilizing water-based inks to produce vibrant colors that adhere well to the transfer film and fabric. Additionally, the quality of adhesive powder greatly influences the longevity and durability of the print. Users should opt for high-grade adhesives that provide strong bonding while remaining flexible enough to accommodate fabric movement.

In addition to the printer and adhesive, a quality heat press is integral to the DTF process. The heat press must provide consistent temperature control and pressure to ensure an effective transfer of the ink onto the fabric. Factors such as the type of fabric, thickness, and required temperature settings can vary significantly, which is why testing different configurations is advised. Properly maintaining these key components not only enhances the quality of the prints but also contributes to the overall efficiency of the printing process.

Step-by-Step Guide to DTF Transfers

Embarking on the DTF transfer journey begins with meticulous design preparation. To achieve the best results, artwork must be created in a high-resolution format, ensuring that every detail translates well onto the DTF film. After preparing the design, you need to load the film into the printer and follow manufacturer-specific recommendations for ink settings. This attention to detail plays a pivotal role in ensuring vibrant and clear prints, which is essential for success in the competitive custom apparel market.

After printing, the careful application of adhesive powder is critical. While the ink is wet, the powder should be evenly sprinkled over the design to bond effectively during the heat transfer process. Once the powder is applied, the print must cure properly using heat, allowing the adhesive to bind securely before the final transfer to the fabric. This comprehensive step-by-step approach not only streamlines the DTF process but also minimizes the likelihood of errors that could compromise the quality of the finished product.

Common Challenges and DTF Transfer Tips

Many users encounter common challenges when beginning with DTF transfers, such as achieving the correct temperature settings and consistent pressure during the transfer process. Brands may offer varying recommendations, but a good rule of thumb is to maintain the heat press temperature around 320°F. Consistency is the key to avoiding issues like peeling or fading, which can diminish the longevity of the designs. Regular monitoring and adjustments based on specific fabric types can help mitigate these concerns.

Furthermore, performing fabric testing plays a critical role in establishing successful DTF transfers. Not all fabrics respond similarly during the transfer process, which is why it’s wise to test a variety of materials—such as cotton, polyester, and blends. By experimenting with different combinations, users can discover the best approaches for their individual projects and ensure the desired outcomes consistently. Employing these tips and insights can significantly enhance the quality and durability of DTF print products.

Unlocking the Advantages of DTF Transfers

DTF transfers provide numerous advantages that make them an appealing choice for custom apparel printing. One of the standout features of DTF printing is its ability to deliver vibrant colors and exceptional graphics on multiple fabric types. Whether for light or dark materials, DTF technology shines, allowing intricate images to pop against any background. This flexibility is invaluable to clothing brands looking to stand out in a saturated market.

In addition to stunning visuals, the cost-effectiveness of DTF printing cannot be overlooked. Unlike screen printing, which may involve extensive setup and material costs, DTF transfers streamline production for small to medium runs without the need for pricey screens. This economic benefit allows creative entrepreneurs to explore their ideas without substantial financial risk, encouraging a more inventive spirit within the custom apparel industry.

Trends Shaping the Future of DTF Printing

The landscape of custom garment printing is rapidly evolving, with DTF transfers at the forefront of this transformation. As more small businesses and creatives adopt this technology, the demand for unique and personalized apparel has surged. Innovations in the DTF printing process, such as improved inks and faster curing techniques, have made the technology more accessible and efficient, further driving its popularity among new entrants in the market.

Additionally, informational resources and communities are burgeoning, aiding designers in mastering the DTF printing process and sharing best practices. Online forums, social media groups, and workshops offer valuable insights into optimizing workflows and troubleshooting common issues. Such connections not only foster a spirit of collaboration but also alleviate some of the learning curves that may slow down newcomers, ultimately paving the way for the growth of a vibrant DTF printing community.

Frequently Asked Questions

What are the key benefits of using DTF transfers for custom apparel printing?

The advantages of DTF transfers include vibrant colors, versatility across different fabric types, cost-effectiveness for small to medium print runs, and an easy-to-master process. With DTF printing, businesses can create stunning designs that appeal to a variety of consumer needs.

How does the DTF printing process work?

The DTF printing process involves printing a design onto specialized DTF film using a compatible printer, applying a high-quality adhesive powder, and then transferring the design onto fabric using a heat press. This method is known for producing highly detailed and colorful prints.

What are some essential tips for successful DTF transfers?

Successful DTF transfers require checking temperature settings for both the heat press and fabric, ensuring consistent pressure during the transfer, fully curing the adhesive, and testing different fabric types for optimal bonding results.

Can DTF transfers be used on various fabric types?

Yes, one of the significant advantages of DTF transfers is their versatility. They work effectively on various fabrics, including cotton, polyester, and blends, making them suitable for both light and dark materials.

What type of printer is best for DTF transfers?

For optimal results in DTF transfers, it’s essential to use a DTF printer that utilizes specialized water-based inks designed for vibrant prints. Ensure that the printer is compatible with DTF films to achieve the best quality and performance.

Is DTF printing considered a cost-effective option for small businesses?

Yes, DTF printing is a cost-effective method for small businesses, particularly for small to medium print runs. Unlike traditional screen printing, DTF does not require screens, allowing for lower start-up costs and faster turnaround times for custom apparel.

| Key Component | Description |

|---|---|

| DTF Printer | Utilizes specialized water-based inks for vibrant results. |

| Adhesive Powder | Bonds ink to fabric during heat transfer; quality is vital. |

| Heat Press | Applies necessary heat and pressure for transfer. |

| DTF Film | Specifically designed for DTF for compatibility and quality. |

Summary

DTF Transfers are revolutionizing the custom apparel industry, allowing for high-quality designs with vibrant colors on various fabric types. By understanding the essential components and following the outlined processes, users can create stunning, durable graphics that cater to diverse consumer needs. This guide not only equips you with fundamental knowledge but also insights into market trends, ensuring that you remain competitive. The future of custom printing is bright with DTF Transfers, paving the way for creativity and innovation in your design ventures.