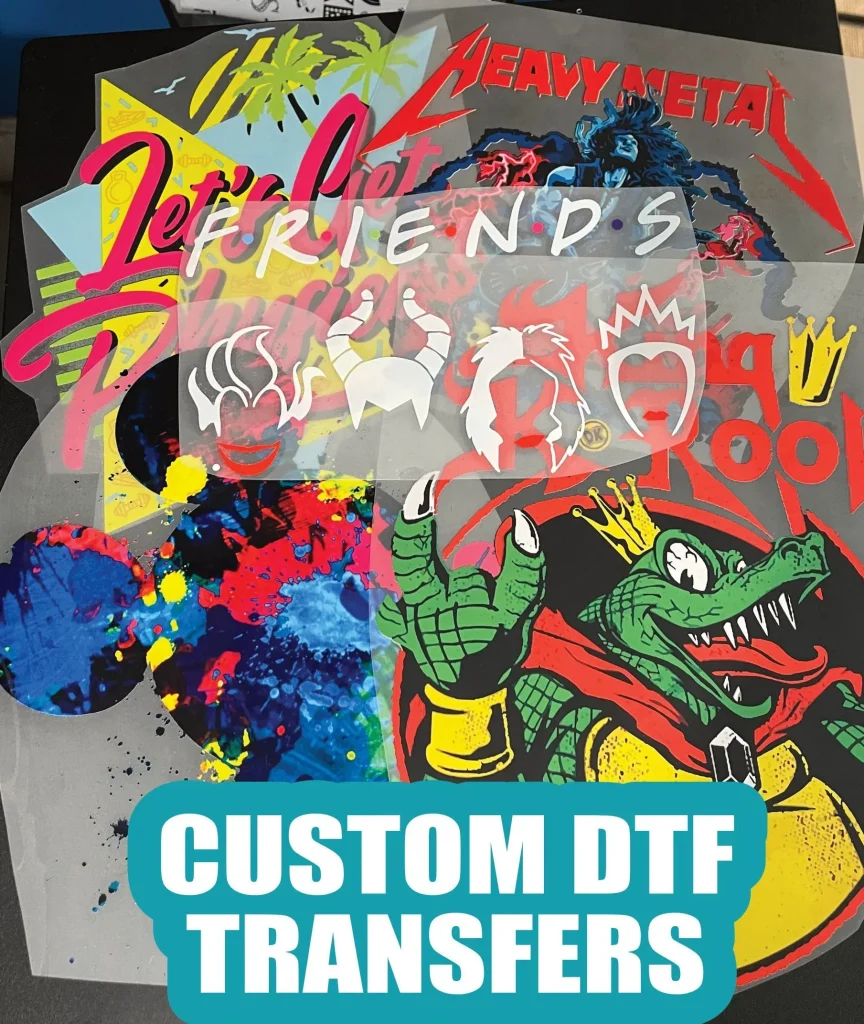

In the dynamic landscape of textile printing, DTF transfers, or Direct to Film transfers, are revolutionizing the way stunning designs are applied to fabrics. This innovative DTF printing process allows for vibrant, detailed images to be transferred onto a variety of materials quickly and efficiently. Businesses and creatives alike are discovering the benefits of DTF printing, including its cost-effectiveness and durability compared to traditional printing methods. Custom DTF prints enable unparalleled design flexibility, making it an appealing choice for a plethora of applications, from apparel to promotional items. As technology progresses, DTF printing technology is set to be at the forefront of custom printing solutions, catering to diverse market demands.

Direct to Film transfers offer a modern approach to fabric printing that emphasizes efficiency and quality. Often referred to within the industry as DTF printing, this technique has gained significant traction due to its ability to produce vibrant, long-lasting prints on various textiles. Whether you’re searching for personalized garments or looking to create promotional products, the advantages of this contemporary printing method are clear. The inherent simplicity of the DTF printing process makes it an excellent choice for businesses facing high customization demands. As the market evolves, utilizing DTF transfers will continue to empower designers and entrepreneurs by providing endless creative opportunities.

Understanding the DTF Printing Process

The DTF printing process, or Direct to Film transfers, is characterized by its simplicity and effectiveness in producing high-quality prints on a variety of fabrics. This begins with a specialized DTF printer that prints vivid designs directly onto a coated film using water-based, pigmented inks. This initial step eliminates the need for direct fabric printing, making DTF a more versatile option. Once printed, the film undergoes a critical step where an adhesive powder is applied, allowing the ink to adhere correctly during the transfer. Through this process, intricate details remain intact, providing an impressive quality that appeals to both businesses and consumers.

After the adhesive powder is applied, the film is cured using a heat press, a pivotal step that solidifies the bond between the ink and the adhesive. This ensures that when the film is later applied to the desired fabric, it results in a durable and vibrant print. The final stage involves a heat transfer process where the cured film is pressed onto the fabric. This activating heat allows the adhesive to create a strong connection, resulting in a high-quality end product. The efficiency of this entire process not only speeds up production but also caters to the growing demand for customized apparel.

The Versatility of DTF Transfers

One of the most significant advantages of DTF transfers is their versatility in application. Unlike traditional printing methods that may be limited to specific garment types or materials, DTF transfers can be effectively applied to a broad selection of fabrics, including cotton, polyester, and blends. This flexibility enables businesses to cater to a wide array of products—from custom t-shirts to promotional merchandise—without worrying about matching fabrics to printing techniques. The ability to print on such diverse materials enhances creativity and expands the possibilities for custom designs.

Moreover, the ability to print vibrant designs on both light and dark fabrics using DTF technology means that creators are not constrained by color limitations. This opens up opportunities for creating unique items that can stand out in a competitive marketplace. The customization potential is further amplified by the low minimum order quantities DTF allows, making it an ideal choice for small businesses and independent designers looking to offer personalized merchandise without the burden of large inventories.

The Benefits of DTF Printing Technology

DTF printing stands out due to its numerous benefits that appeal to both entrepreneurs and consumers. One primary advantage is its cost-effectiveness, particularly for small batch jobs. Unlike Direct to Garment (DTG) printing, DTF transfers do not require specialized garments or extensive setup, making it an appropriate option for businesses looking to minimize expenses while still delivering top-quality products. As such, entrepreneurs can experiment with new designs without financial constraints, fostering innovation and customer engagement.

Durability is another critical benefit, as DTF prints are known for maintaining their vibrancy and integrity even after multiple washes. This durability ensures that clothing remains appealing long after purchase, elevating customer satisfaction and encouraging repeat business. Furthermore, the efficiency of the DTF process allows for quicker production times and easier adjustments during printing, which is particularly beneficial for businesses facing tight deadlines and high volume demands such as seasonal merchandise.

Market Trends in DTF Printing

As the DTF printing market continues to grow, several key trends are shaping its trajectory. Innovations in DTF technology play a significant role, with manufacturers consistently developing advanced printing equipment and eco-friendly adhesive formulations. The enhanced quality and efficiency resulting from these innovations not only improve the overall printing process but also align with the increasing demand for sustainable practices. Businesses are finding that DTF printing can be environmentally friendly, appealing to consumers who prioritize sustainability in their purchasing decisions.

Furthermore, there is a surging demand for customized products across various industries, fueling the growth of DTF printing. Businesses are now able to offer personalized apparel with low minimum order requirements—an attractive feature for niche markets and on-demand needs. This capability is leading to an explosion of creativity in product offerings, ranging from unique gifts to branded merchandise, asserting DTF as a crucial player in the custom printing sector.

Challenges Faced with DTF Transfers

Despite the impressive advantages of DTF transfers, there are challenges that businesses must consider. Quality control presents a significant hurdle; the final output can vary based on various factors such as printer settings, ink quality, and operator skill level. Achieving consistent results requires careful setup and calibration, alongside rigorous maintenance of the printing equipment. These factors can impact production timelines and customer satisfaction if not adequately addressed.

Additionally, while DTF technology can provide a cost-effective solution for small runs, the initial investment required for high-quality DTF printers and necessary materials can be steep. Businesses need to carefully evaluate the costs associated with obtaining such equipment against the potential benefits, especially if they are new to this technology. Understanding these challenges is essential for companies looking to implement DTF transfers successfully in their workflow.

Conclusion: The Future of DTF Printing

DTF transfers have emerged as a transformative force in textile printing, offering businesses and consumers alike a flexible, efficient, and high-quality solution. As technology continues to advance, DTF is positioned to evolve further, solidifying itself as a staple in the custom apparel and promotional merchandise industries. By understanding the inherent benefits and challenges associated with DTF printing, businesses can make informed decisions that drive their success in a competitive market.

The growing significance of customization, sustainability, and technological innovation in the printing sector underscores the relevance of DTF transfers in today’s landscape. Companies that embrace this innovative technology can meet the demands of a changing marketplace, ensuring they stay relevant and competitive. For those interested in exploring the full capabilities of DTF printing, now is the perfect time to dive into this exciting world and leverage its potential to cater to evolving customer needs.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs directly onto a special film, which is then transferred to fabric. The process includes printing, applying adhesive powder, curing the design, and heat transferring it to various materials, allowing for vibrant and durable images on textiles.

What are the key benefits of using DTF printing technology?

The benefits of DTF printing technology include versatility in application on different fabric types, cost-effectiveness for small runs, durability of prints that withstand multiple washes, and a simplified production process that allows for quick turnarounds.

How does the DTF printing process compare to other printing methods?

Compared to other printing methods like Direct to Garment (DTG), DTF printing offers lower costs for small orders, greater versatility across material types, and often better durability. These factors make DTF an attractive option for businesses seeking efficient and high-quality solutions.

Can DTF transfers be used for custom DTF prints?

Yes, DTF transfers are ideal for creating custom DTF prints. They enable businesses to produce personalized apparel and promotional items with intricate designs and low minimum order requirements, catering to the growing demand for customized products.

What challenges should businesses be aware of when using DTF transfers?

When using DTF transfers, businesses should consider challenges such as potential variations in print quality depending on printer setup and maintenance, as well as the initial equipment investment needed for DTF technology. Proper expertise is essential to ensure consistent results.

What market trends are influencing DTF printing today?

Current market trends influencing DTF printing include innovation in technology leading to improved print quality, rising demand for custom apparel, and an increasing focus on eco-friendly practices. DTF technology aligns well with the need for sustainability in the printing industry.

| Key Aspect | Description |

|---|---|

| What are DTF Transfers? | A modern printing method allowing vibrant images to be printed on special film and transferred onto various fabrics, eliminating intermediate steps. |

| Printing Process | 1. Printing on Film – Designs are printed on a coated film using water-based pigments. 2. Applying Adhesive Powder – Adhesive is applied to wet ink to ensure adherence. 3. Curing – Adhesive bonds to the ink using heat. 4. Heat Transfer – Bonding of design to fabric using a heat press. |

| Benefits | – Versatility in application across various materials. – Cost-effective for small runs, good for businesses. – Highly durable withstanding multiple washes. – Simplifies production enabling quicker turnarounds. |

| Market Trends | – Continuous advancements in printing technology. – Increased demand for customized apparel. – Adoption of eco-friendly practices in printing processes. |

| Challenges | – Quality control can vary based on equipment and expertise. – High initial investment costs for setup. |

Summary

DTF transfers have revolutionized the field of textile printing, providing a streamlined approach that efficiently prints high-quality designs onto various fabrics. With their adaptability and durability, DTF transfers cater to diverse markets, from custom apparel to promotional products. As advances in technology continue, businesses are better poised to meet increasing consumer demands for personalization while also considering sustainability in their production processes. Understanding the nuances of DTF transfers, including their benefits and challenges, empowers entrepreneurs and creators to embrace this innovative printing solution confidently.