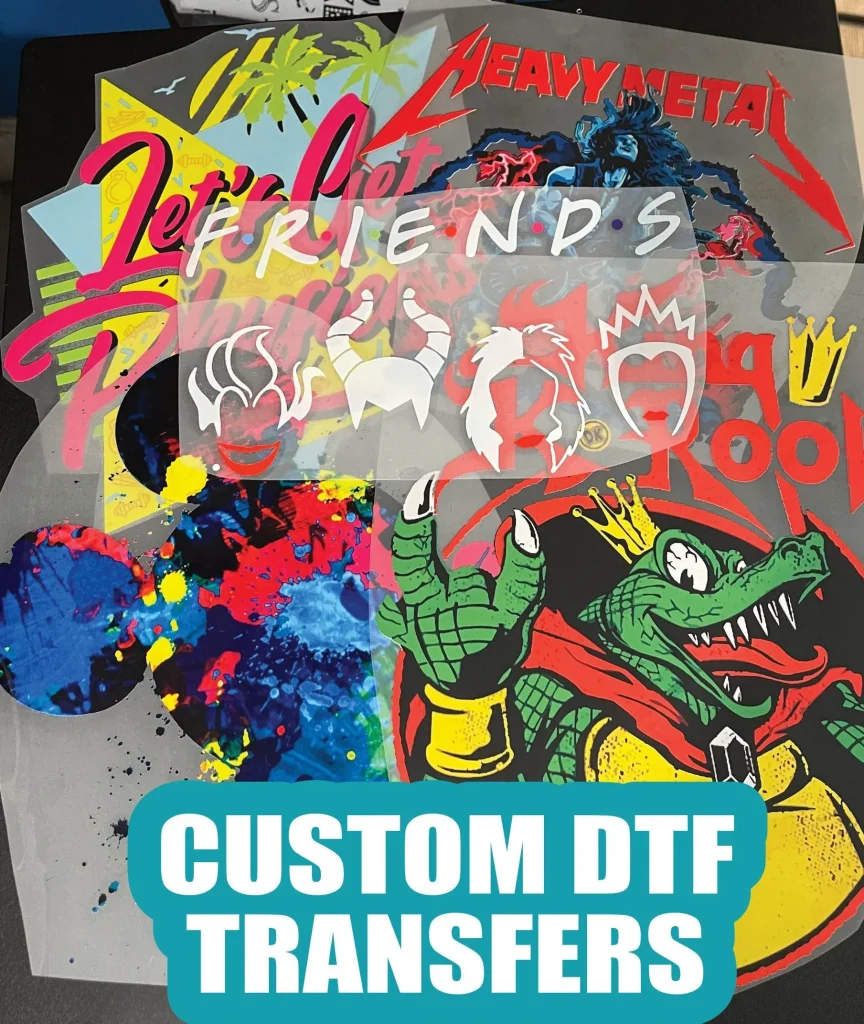

DTF transfers, or Direct-to-Film transfers, are transforming the realm of custom apparel, offering a revolutionary approach to t-shirt printing and textile design. This cutting-edge printing technology allows for vibrant, detailed artwork to be printed on a special transfer film, which is then effortlessly applied to various fabrics. With advantages such as high-quality output and the flexibility to work with multiple materials, DTF is rapidly becoming a preferred method for designers and businesses alike. Not only is DTF printing cost-effective, but it also boasts rapid turnaround times, making it a game changer for urgency-driven projects. As we delve deeper into the mechanics and benefits of DTF transfers, it becomes clear that this printing solution is reshaping the landscape of custom apparel.

Known in the industry as Direct-to-Film printing, this innovative printing method is quickly gaining traction in the textile printing sector. Functioning through an advanced technique that transfers designs onto film before application, this approach eliminates many of the constraints associated with traditional custom apparel methods. The versatility inherent in this printing technology allows for a wide range of garment types and designs, making it suitable for everything from t-shirt printing to highly specialized apparel. As the demand for personalized clothing continues to grow, alternatives such as DTF printing offer solutions that are both efficient and visually stunning. By focusing on quality and ease of use, this technique stands out as a pivotal player in the burgeoning market of custom clothing.

Understanding DTF Transfers: The Basics

Direct-to-Film (DTF) transfers are at the cutting edge of printing technology, designed to deliver high-quality designs on various fabrics. The process begins with a specialized transfer film, where intricate designs are printed using advanced DTF printing techniques. This allows for detailed and colorful artwork to be transferred onto apparel like t-shirts and hoodies effortlessly. Our understanding of DTF transfers is paramount as it revolutionizes the way we perceive custom apparel in today’s market.

The basic principle behind DTF transfers is straightforward: ink is printed onto a film that is then heat-pressed onto the fabric. This method ensures that vibrant colors and intricate details are preserved, enhancing the overall quality of the finished product. Unlike screen printing, which requires complex setups and is often limited to certain materials, DTF printing offers unparalleled versatility, making it ideal for diverse fabric types, including both light and dark garments.

Why DTF Transfers are Essential in Custom Apparel

In the realm of custom apparel, DTF transfers could be deemed essential due to their unrivaled quality and adaptability. Unlike other printing methods, DTF technology supports vibrant designs on a wide array of fabric types, which caters to the ever-evolving demands of the market. As custom brands emerge and evolve, the capability to produce high-quality, colorful items quickly and without significant upfront costs becomes increasingly important.

Moreover, DTF transfers have democratized the custom apparel printing process, allowing small businesses and independent creators access to professional-grade printing tools. This accessibility not only fuels creativity but also helps in catering to niche markets where personalization is key. Hence, understanding DTF transfers is vital for anyone looking to make a mark in the custom apparel space.

Comparing DTF Transfers with Screen Printing and Sublimation

When evaluating printing options, one of the most common comparisons made is between DTF transfers, screen printing, and sublimation. Each of these methods has distinct advantages, but DTF printing excels in its flexibility. For instance, while screen printing is renowned for producing high-quality prints, it requires significant setup time and is less suitable for small batches. In contrast, DTF allows for quick turnarounds on even limited orders, making it a more viable option for custom apparel.

On the other hand, sublimation printing is primarily effective on polyester fabrics and tends to yield soft and durable results. However, its limitations include an inability to print on darker materials. DTF technology, in contrast, offers the freedom to work on both light and dark fabrics, broadening the scope of designs a creator can execute. This understanding makes DTF printing a comprehensive choice for businesses aiming for versatility in their printing capabilities.

Latest Innovations in DTF Printing Technology

The world of DTF printing technology is evolving at a rapid pace, with recent developments significantly enhancing its appeal to businesses and creators alike. Innovations such as the launch of dedicated DTF platform services have simplified the printing process for users, making it easier to create and print transfers without the complexities associated with traditional methods. The introduction of web-to-print portals allows for a more streamlined approach, catering to the increased demand for efficient custom apparel solutions.

Companies are also bolstering their capabilities by acquiring advanced printers and introducing same-day shipping options. This reflects a significant shift in the industry as businesses strive to remain competitive while meeting the growing consumer expectation for fast and high-quality custom products. As these innovations continue to unfold, DTF printing technology is increasingly positioned to redefine standards in the textile printing landscape.

The Economic Benefits of DTF Transfers in Custom Apparel

DTF transfers present an array of economic advantages, particularly for businesses aiming to optimize production costs. The affordability of the DTF printing process makes it an attractive option for small businesses and creative entrepreneurs. Unlike traditional methods like screen printing, DTF transfers require minimal initial investment, allowing startups to jump into the custom apparel market without the burden of hefty equipment costs.

Moreover, DTF technology minimizes waste, as it permits on-demand production of custom designs, eliminating the need for excessive inventory. This efficiency not only aids in managing operating expenses but also enhances sustainability practices—a significant consideration for modern consumers. Overall, understanding the economic benefits of DTF printing can empower businesses to make informed decisions while striving for profitability in the competitive custom apparel sector.

Looking Ahead: The Future of DTF Printing in Custom Apparel

As we look towards the future, the potential of DTF printing within the custom apparel industry appears boundless. With ongoing advancements in technology and increasing education initiatives surrounding DTF processes, creators are bound to benefit from enhanced knowledge and skills. The evolving landscape means that DTF will likely continue to assert its presence as a dominant player in the textile printing industry.

Furthermore, the adaptability and versatility of this printing method make it suitable for a variety of applications, from promotional wear to personalized gifts. As more businesses begin experimenting with DTF printing, we can expect a growing number of creative, innovative products that cater to diverse consumer needs. The continuous influx of resources and educational content aligns perfectly with the upward trajectory of DTF technology in the custom apparel market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film and then applying these designs to fabrics using heat and pressure. This innovative printing technology allows for vibrant, intricate designs on various materials, making it a preferred choice for custom apparel such as t-shirts and hoodies.

How do DTF transfers compare to other custom apparel printing methods?

Compared to other methods like screen printing and sublimation, DTF transfers offer greater versatility by being applicable on both light and dark fabrics. While screen printing is better for larger batches, DTF is ideal for small orders due to its low setup costs and quick turnaround time.

What advantages do DTF transfers offer for textile printing?

DTF transfers provide several advantages in textile printing, including high-quality output, cost-effectiveness, and rapid production times. This method caters to a wider range of fabrics and designs, allowing for more flexibility and creativity in custom apparel creation.

Are DTF transfers suitable for all types of fabrics used in custom apparel?

Yes, DTF transfers are suitable for a variety of fabrics, including cotton, polyester, and fabric blends. This adaptability makes them an excellent choice for various custom apparel projects, ensuring vibrant designs across different textiles.

How can businesses benefit from adopting DTF printing technology?

Businesses can benefit from DTF printing technology through its cost-effectiveness, rapid production capabilities, and the ability to create high-quality custom apparel without significant upfront investment. DTF allows small businesses to offer a diverse range of products to meet customer demands efficiently.

What recent developments are shaping the future of DTF transfers?

Recent developments in DTF printing technology include the launch of user-friendly platforms like DTFPrinter and the expansion of services by companies like Eazydtf. These innovations improve access to DTF technology, educate users, and streamline the custom printing process, contributing to the growth of the DTF market in the custom apparel industry.

| Aspect | Details |

|---|---|

| Introduction | DTF Transfers are revolutionizing custom apparel with innovative printing techniques. |

| Definition | DTF transfers print designs on a special film, which are then applied to various fabrics. |

| Advantages | Quality, versatility across fabrics, cost-effective for small businesses, and rapid turnaround. |

| Recent Innovations | Platforms like DTFPrinter and Snuggle DTF improve access and ease of use for DTF services. |

| Comparison with Other Methods | DTF is adaptable for both light and dark fabrics, unlike sublimation which is limited. Easier for small runs compared to screen printing. |

| Future Outlook | With ongoing advancements, DTF Transfers are expected to significantly influence the custom apparel market. |

Summary

DTF Transfers represent a groundbreaking approach in the custom apparel industry. By providing a unique blend of quality, cost-effectiveness, and rapid production capabilities, DTF Transfers are reshaping the landscape of garment printing. Recent innovations in technology have simplified the creation and application of these transfers, making them accessible to businesses of all sizes. As more companies adopt DTF Transfers, the potential for vibrant and diverse custom designs continues to expand, setting a new standard in the world of custom apparel.