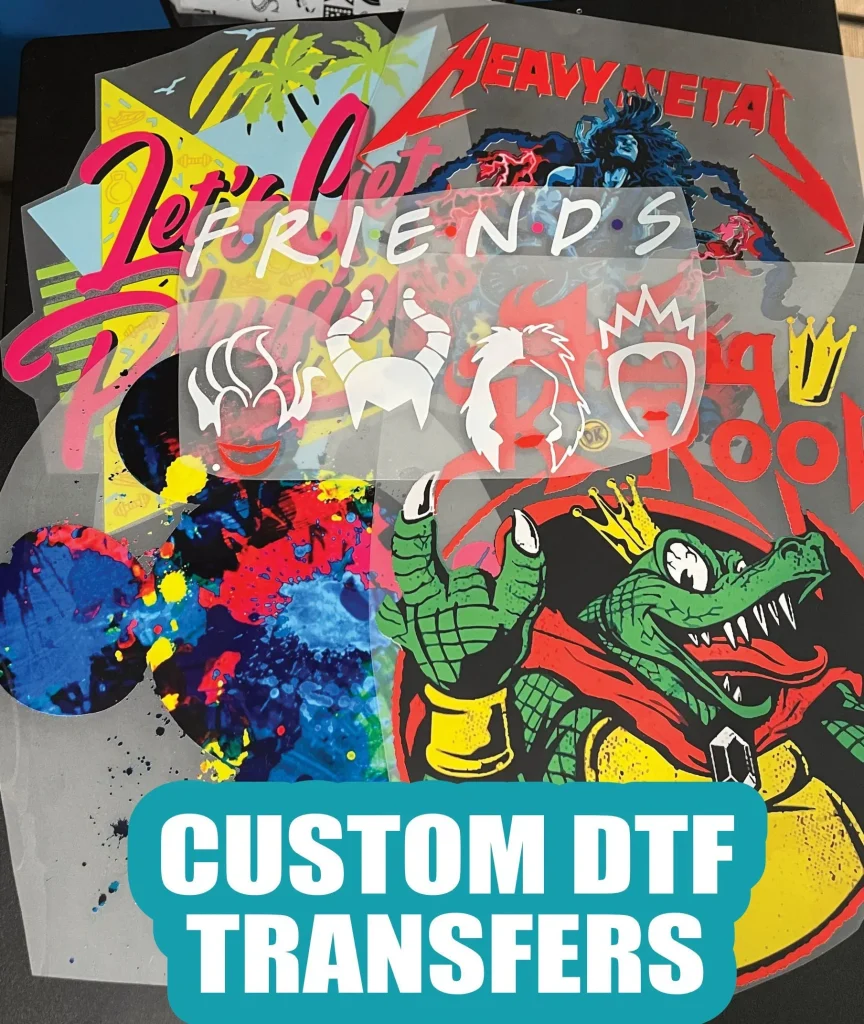

DTF transfers, or Direct-to-Film transfers, are at the forefront of modern printing technology, redefining how custom apparel is created. This innovative technique allows vibrant designs to be printed directly onto a specialty film, which is then transferred onto a variety of fabrics using heat and pressure. With its remarkable adaptability and high-quality output, DTF printing is rapidly gaining popularity among businesses and individuals involved in garment production. From intricate graphics to bold colors, DTF transfers provide a unique solution for those looking to create exceptional custom clothing. As the demand for personalized apparel surges, understanding the capabilities and benefits of DTF transfers becomes increasingly essential for standing out in a competitive market.

Direct-to-Film printing, often referred to as DTF technology, is transforming the landscape of apparel decoration with its advanced capabilities. This technique involves using specialized transfer films to produce striking, detailed prints that can be easily applied to various fabric types. The versatility of this method supports a wide range of custom designs, catering to both business operations and personal projects alike. Additionally, the introduction of gang sheets within this printing process maximizes efficiency, making it easier to produce multiple designs on a single sheet. As this technology continues to evolve, embracing the potential of DTF transfers could pave the way for new creative opportunities in the custom apparel industry.

Understanding DTF Transfers: A Modern Printing Solution

Direct-to-Film (DTF) transfers are at the forefront of modern printing technology, providing a unique approach to customizing apparel. This innovative technique allows for detailed designs to be printed on a specialized film, which can then be easily transferred onto various fabric materials. Unlike traditional printing methods, DTF is not limited by the type of fabric, making it a versatile option for companies looking to offer a wide range of custom apparel. From cotton to blends and synthetics, DTF ensures high-quality results with the ability to produce vibrant colors and intricate details.

The process of creating DTF transfers involves printing directly onto a film using eco-friendly, water-based inks. Once printed, the film is equipped with a heat-activated adhesive that allows it to bond with the fabric during the transfer process. This method not only simplifies the printing workflow but also enhances the durability of the designs, as DTF prints can withstand regular wash cycles without fading or peeling. As a result, businesses can confidently offer stylish and long-lasting custom clothing options to their customers.

The Evolution of DTF Printing Technologies

In recent years, the advancements in DTF printing technology have led to remarkable improvements in both efficiency and quality. Companies like EazyDTF have significantly expanded their production capacities by investing in large-format printers, allowing for faster turnaround times and higher output of DTF transfers. This evolution has made it possible for businesses to meet the growing demands of the custom apparel market, providing same-day shipping options for their clients.

Moreover, the introduction of new gang sheet techniques has optimized the printing process by allowing multiple designs to be printed on a single sheet. This not only helps in reducing material costs but also enhances production efficiency. As businesses become more adept at utilizing these technological advancements, the quality and variety of designs available through DTF printing continue to increase, offering endless possibilities for customization in the fashion industry.

Benefits of Using DTF Transfers for Custom Apparel

One of the key advantages of DTF transfers is their versatility across different fabric types. This flexibility allows businesses to cater to various market segments by providing customized options for t-shirts, hoodies, hats, and more. DTF transfers are particularly appealing for small businesses and startups, as they allow for cost-effective low-volume production without the significant setup costs associated with traditional screen printing.

Additionally, the durability of DTF prints is a major selling point for custom apparel. Unlike other printing methods that may fade or wear out over time, DTF transfers have a strong adhesive that bonds well with the fabric. This ensures that designs maintain their vibrant colors and intricate details even after numerous washes. Ultimately, this longevity not only enhances customer satisfaction but also solidifies the brand’s reputation for quality.

Exploring Gang Sheets in DTF Printing

Gang sheets are a game-changer in the realm of DTF printing, allowing businesses to maximize their productivity and cost efficiency. By combining multiple designs on a single transfer sheet, companies can print several small orders at once without the need for additional setup, saving both time and resources. This method is especially beneficial for graphic designers and small apparel brands looking to offer personalized products without the burden of large minimum order quantities.

Furthermore, the use of gang sheets not only streamlines the printing process but also minimizes material waste. Because multiple designs are printed in one go, businesses can optimize their ink usage and reduce excess film materials, contributing to a more sustainable operation. As eco-conscious practices become more important in the garment industry, utilizing gang sheets in DTF printing can help companies align with sustainability goals while maximizing their production efficiency.

Comparing DTF Printing with Other Techniques

When evaluating DTF printing against other popular techniques like sublimation and screen printing, several factors come into play, including material compatibility, cost-effectiveness, and printing quality. DTF printing excels when it comes to versatility, as it can be used on a wider range of fabrics compared to sublimation, which requires polyester or synthetic materials for optimal results. In contrast, DTF transfers can effectively be applied to cotton and blended fabrics, making them a preferred choice for many apparel businesses.

Additionally, DTF printing falls on the more affordable side for small-run custom orders. This is particularly advantageous for startups or designers who wish to produce unique items without significant initial investment in equipment or materials. As customers increasingly seek personalized fashion, understanding the benefits and limitations of each printing technique can guide businesses in choosing the best method for their specific needs.

Tips for Successful DTF Transfer Production

Achieving high-quality results with DTF transfers requires attention to detail and proper preparation. One of the most critical aspects is selecting the right materials, including high-quality inks and films, which can significantly affect print results. Using inferior materials can lead to disappointing outcomes, such as poor adhesion and fading colors. Therefore, investing in premium supplies can help ensure vibrant, longevity prints that meet customer expectations.

In addition to material quality, proper curing of the transfers is crucial for durability. It’s essential to adjust heat press settings according to the specifications of the fabric being used to achieve the best results. This includes not only temperature but also pressure and dwell time. By taking the time to optimize each step of the DTF printing process, businesses can enhance their overall production quality and deliver exceptional custom apparel that stands out in the marketplace.

Frequently Asked Questions

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages for custom apparel, including versatility to print on various fabrics, high-quality vibrant colors, durability that withstands washing, and cost-effectiveness for small production runs. This makes DTF printing an ideal choice for businesses looking to expand their custom clothing offerings.

How do DTF transfers compare to sublimation printing?

DTF transfers and sublimation printing differ primarily in fabric compatibility and print quality. While sublimation works best on polyester and requires a specific substrate, DTF transfers can be used on a wider range of fabrics, including cotton and blends, making them more versatile for custom apparel.

What are gang sheets, and how do they benefit DTF printing?

Gang sheets are a technique used in DTF printing where multiple designs are printed on a single film sheet. This method optimizes material usage, reduces waste, and lowers costs, making it ideal for businesses looking to maximize efficiency in custom apparel production.

What recent advancements are notable in DTF printing technology?

Recent advancements in DTF printing technology include expansions by companies like EazyDTF, which now offer same-day shipping of DTF transfers, and the introduction of high-capacity trade services by Snuggle, which produces thousands of transfers daily, reflecting the growing demand in the custom apparel sector.

How can I achieve high-quality results with DTF transfers?

To achieve high-quality results with DTF transfers, use high-quality inks and films, ensure proper curing of prints to enhance durability, and optimize your designs using suitable software. Effective use of gang sheets can also improve production efficiency while maintaining design fidelity.

Is DTF printing cost-effective for small businesses producing custom apparel?

Yes, DTF printing is cost-effective for small businesses, as it allows for smaller production runs without the significant setup costs associated with traditional screen printing. This flexibility makes it accessible for those starting out or those requiring custom orders.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Printing designs on film and transferring to fabric using heat and pressure. |

| Recent Developments | EazyDTF expands capacity; Snuggle offers trade service; educational guides on gang sheets; comparisons with sublimation printing. |

| Why Choose DTF Transfers? | Versatile, high-quality, durable, and cost-effective for small runs. |

| Techniques for Successful DTF Printing | Use quality materials, ensure proper curing, and optimize designs. |

Summary

DTF Transfers have emerged as a revolutionary printing method that is transforming the custom apparel industry. By utilizing advanced technology and providing unmatched versatility, DTF transfers allow for vibrant and long-lasting prints on a variety of fabrics. The evolving capabilities of DTF printing, highlighted by significant market players such as EazyDTF and Snuggle, underscore the increasing demand and innovation in this sector. For anyone looking to explore custom garment printing solutions, DTF transfers represent a cost-effective and adaptable option that is well worth considering.